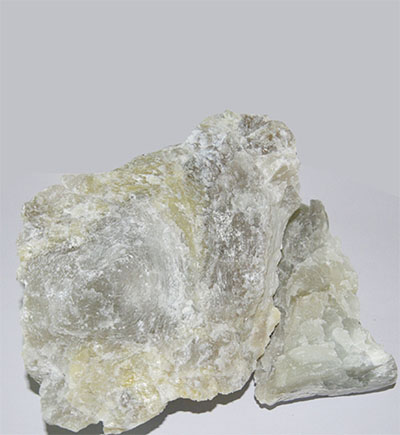

The microstructure of the magnesia brick is actually the combination of the magnesia microstructure. The microstructure of the magnesia brick produced by one kind of raw material is the simplest. A magnesia brick made from British seawater magnesia, with almost no silicate except for pores in the matrix. Within the magnesite crystal, the intercrystalline micropores are characteristic structural parameters. High-purity magnesia bricks produce magnesia bricks mainly rely on the sintering of liquid phase in the magnesia powder matrix to achieve the combination of particles. Therefore, the raw materials with high purity are difficult to be sintered, and the bricks made with seawater magnesia should be 1700~1800°C or even 1850°C. The above temperature is fired. Bricks containing more silicate (CMS) can be sintered at 1500~1600 °C. Therefore, it is common for ordinary magnesia bricks to be dense, and the seawater magnesia brick matrix to be porous. However, it is reflected in the high temperature mechanical properties, but it has the opposite result. For example, the load softening temperature of seawater magnesia brick is higher than 1700 °C; the general sintered magnesium brick is 1500~1600 °C. Foreign production of high-purity magnesia bricks is mostly combined with seawater magnesia or seawater magnesia and fused magnesia.

tel:+86-0412-7823890 Mobile phone:+86-13804925659![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

fax:0412-7821123 email:lnhyky@126.com

Address: 16-1, the fourth phase of the Jade Pearl of Silk Road, Xiuyan County, Anshan City, Liaoning Province

Sweep, learn more +