The load-softening temperature of aluminum-magnesium carbon bricks is much lower than the degree of refractoriness, which is about 1500 °C. The reason is thermal expansion and thermal shock stability

The thermal expansion of magnesia bricks is large, and the coefficient of linear expansion increases with increasing temperature. The thermal shock stability of magnesia bricks is poor, and the number of water cooling is only 2~3 times. The reason is that the coefficient of thermal expansion is large and the temperature conductivity is poor. When the temperature changes rapidly, it is easy to generate large thermal stress. The CMS in the matrix has anisotropy. When the temperature changes rapidly, the thermal stress is intensified due to the difference in the expansion. The solubility of periclase to magnesium ferrite varies with temperature. The incorporation and precipitation of magnesium ferrite also leads to the generation of internal stress; the elastic modulus of magnesia brick is higher, and the buffering ability to stress is weaker. Therefore, it is easy to swell and is easily cracked, that is, the thermal expansion property is large and the thermal shock stability is poor. There are a variety of compounds and eutectic compounds in the matrix. These eutectic compounds have a lower melting point. For example, the eutectic point of MF-CMS is 1430 ° C. The eutectic point of CMS is 1330 ° C. At the same time, the low melting point eutectic compound evenly surrounds the periclase particles, so that no skeleton can be formed between the particles. When the temperature rises, the low melting point eutectic compound melts and causes the magnesia brick to soften and deform, so the load of the magnesia brick The softening temperature is low. High refractoriness and low softening temperature are another significant feature of magnesia bricks.

Refractoriness

The melting point of periclase is as high as 2800 ° C. Therefore, the refractoriness of magnesia bricks is also very high, generally up to 2000 ° C.

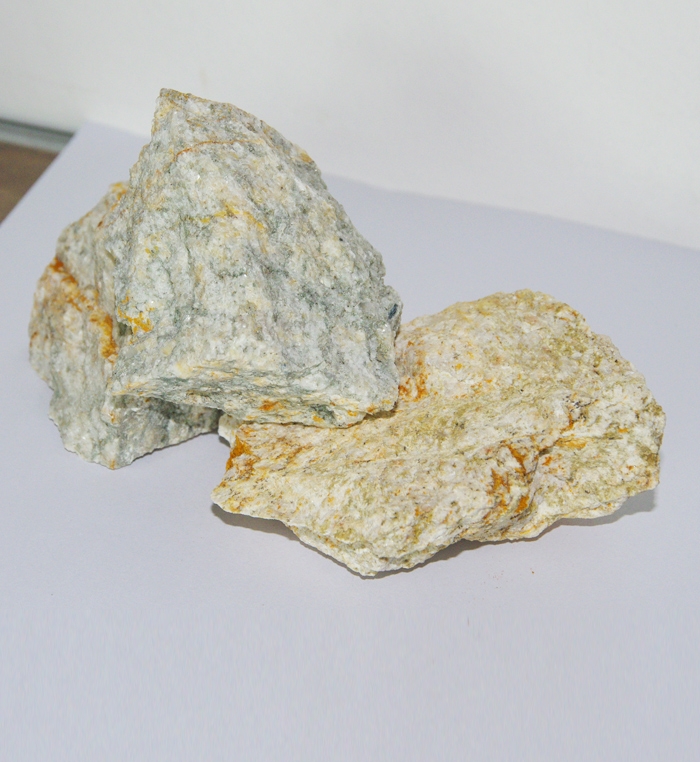

Tundish wet and dry material, tundish spread material, intermediate package slag wall, magnesium brick manufacturer thermal conductivity and temperature guide magnesia manufacturer, magnesium brick manufacturer, amorphous refractory material, to Haicheng Tianxing refractory, including tundish wet and dry The material, the tundish spread, the intermediate package slag wall, the thermal conductivity of the magnesia brick is good, but the thermal conductivity decreases significantly with increasing temperature. Due to the large heat capacity and bulk density of the magnesia brick, although the thermal conductivity is large and the temperature conductivity is poor, that is, the temperature changes slowly. Good thermal conductivity and poor temperature conductivity are another significant feature of magnesia bricks.

tel:+86-0412-7823890 Mobile phone:+86-13804925659![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

fax:0412-7821123 email:lnhyky@126.com

Address: 16-1, the fourth phase of the Jade Pearl of Silk Road, Xiuyan County, Anshan City, Liaoning Province

Sweep, learn more +