Characteristics and uses of magnesium-aluminum brick and magnesium brick wholesale

Characteristics and uses of aluminum-magnesium carbon brick

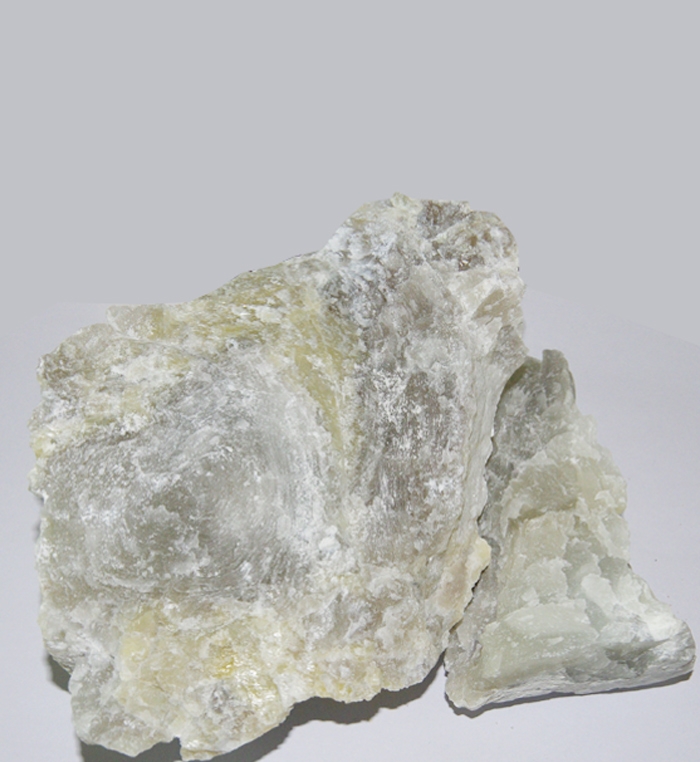

Magnesia sand is used as the main raw material, magnesia and bauxite are used as the matrix for co-grinding fine powder. The alkaline product which is fired at high temperature is called magnesium aluminum brick, magnesia aluminum brick magnesia aluminum spinel brick magnesium spinel brick magnesium Aluminum series

Also known as the magnesia spinel brick.

Magnesium-aluminum brick has good thermal shock resistance, high temperature mechanical strength, high load softening temperature, good slag resistance, high temperature performance and thermal stability. It has been widely used in steel furnace flat roof, and is still used in ladle. , steelmaking furnace lining, glass kiln regenerator, mixed iron furnace, copper refracting kiln roof and refractory industrial high temperature kiln.

Magnesia-aluminum bricks made of magnesia and spinel are magnesium spinel bricks, also known as second-generation magnesium-aluminum spinel bricks.

The successful development of magnesium-aluminum bricks has made important contributions to the development of China's metallurgical industry. In the new generation, there are not many manufacturers producing such bricks, mostly because the temperature of the kiln is not up to standard.

At present, magnesia-aluminum bricks are mostly used in non-ferrous smelting, cement kiln front and rear transition zones, lime kiln high temperature zones, glass regenerative furnaces, and reverberatory furnace roofs.